Humanoid robots are finally emerging from their infancy

A few years ago, humanoid robots were clumsy and uncomfortable to watch moving around. Now, several

startups claim to have models almost ready to go to work in warehouses and factories.

Eight years ago, the Pentagon’s Defense Advanced Research Projects Agency (DARPA) held a disastrous competition in which robots struggled to perform a series of human tasks, such as opening doors, operating power tools, and driving golf carts, in very slow steps. They frequently failed. Of course, videos of the DARPA Robotics Challenge soon went viral.

Today, the descendants of those ill-fated robots are far more capable and graceful. Several startups are developing humanoids that they say could be working in warehouses and factories within a few years.

Astro Amazon Robot

Astro is currently invitation-only. The robot incorporates new surveillance capabilities, a mobile extension of Amazon’s surveillance network.

Humanoid robots almost ready to work

Jerry Pratt, a senior research scientist at the Institute for Human and Machine Cognition, a nonprofit research center in Florida, led a team that placed second in the 2015 DARPA competition. He is currently chief technology officer of Figure AI , a company developing a humanoid robot designed to work in warehouses and which recently announced a $70 million investment.

Pratt says that if DARPA’s challenge were run today, robots would be able to complete the challenges in about a quarter of the 50 minutes it took his prototype to complete the course, with few accidents. “From a technical standpoint, there have been a lot of technologies that have emerged recently that make this possible,” he says.

More advanced computer vision , made possible by advances in machine learning over the past decade, has made it much easier for machines to navigate complex environments and perform tasks like climbing stairs and grasping objects. Higher-powered batteries , created by the development of electric vehicles , have also made it possible for a humanoid robot to move its legs quickly enough to dynamically maintain balance — that is, to stabilize itself when it slips or stumbles while taking a step, just as humans do.

Pratt says his company’s robot is taking its first steps in a simulated warehouse in Sunnyvale, California. Brett Adcock, CEO of Figure AI, estimates that it should be possible to manufacture humanoids at the same cost as a car, assuming there is enough demand to scale up production.

If Adcock is right, the field of robotics is approaching a pivotal moment . You’re probably familiar with the Atlas humanoid robots , which have been racking up likes on YouTube for several years. They’re made by Boston Dynamics , a pioneer of legged locomotion that built some of the humanoids used in DARPA’s competition, and they demonstrate that it’s possible to build competent, human-shaped robots . But these models have proven extremely expensive and lacked the software needed to make them autonomous and useful; the original Atlas cost several million dollars.

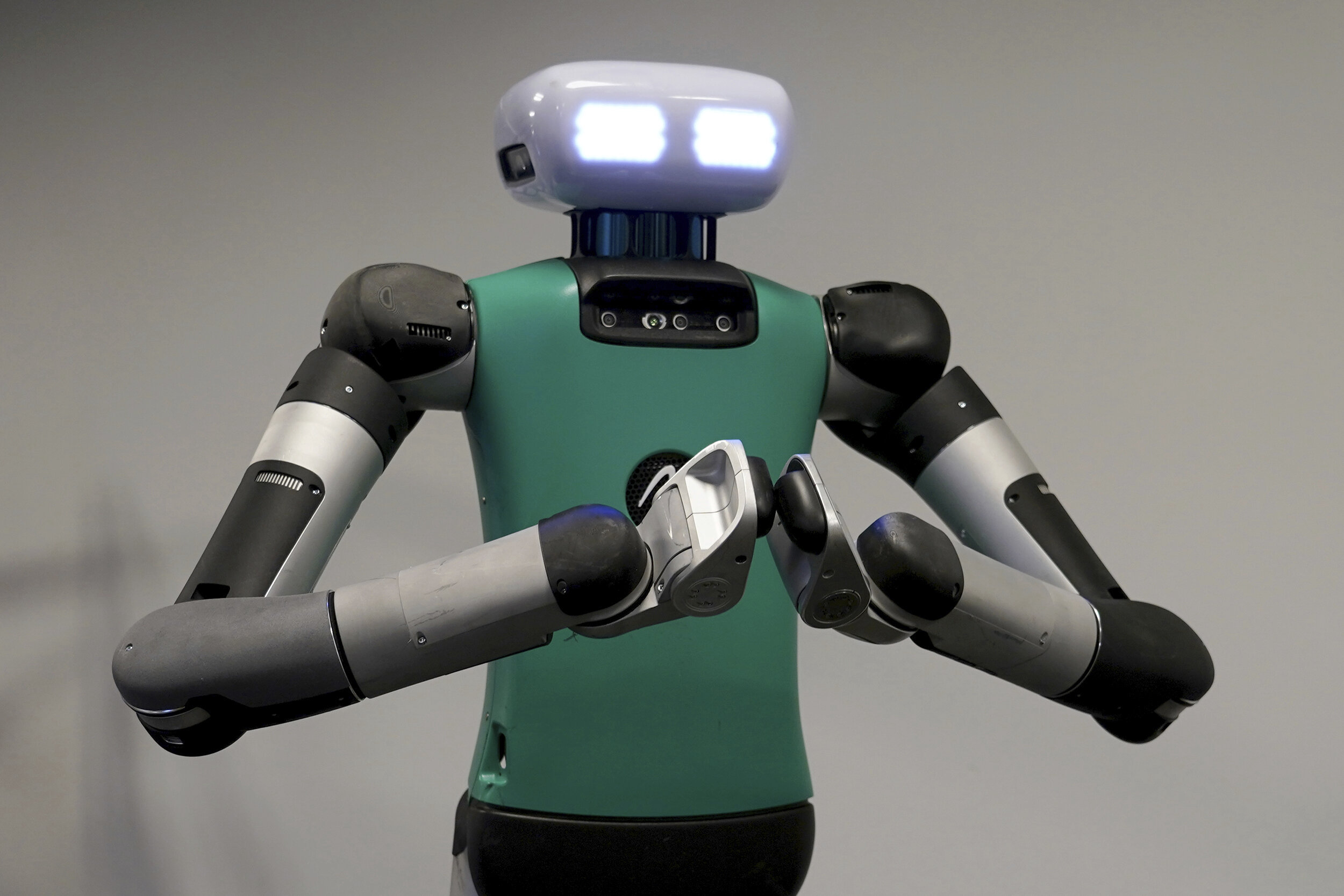

Figure AI isn’t the only company betting on the mature stage of humanoid robots . Others include 1X , Apptronik , and Tesla . Tesla CEO Elon Musk attended the inaugural DARPA Robotics Challenge in 2015. The fact that he’s now willing to build a humanoid on his own suggests that some of the technologies needed to make such a machine are finally viable.

Jonathan Hurst, a professor at Oregon State University and co-founder of Agility Robotics, was also in the DARPA competition to demonstrate a walking robot they built. The company has been working on legged robots for some time , but Hurst says it has taken a physics-based approach to locomotion rather than copying the mechanics of human limbs. Although his robots are humanoid, they have limbs that appear to be inspired by those of an ostrich.Most viewed

- ScienceThe inhabitants of Easter Island arrived in America hundreds of years before Christopher Columbus.By Jorge Garay

- ScienceStrange structure discovered in the confines of the Solar SystemBy Sara Carmignani

- SecurityHow to know if someone is using or spying on your WhatsApp from another device?By Fernanda Gonzalez

- Security The 15 most powerful armies in the world By Kevin Carboni

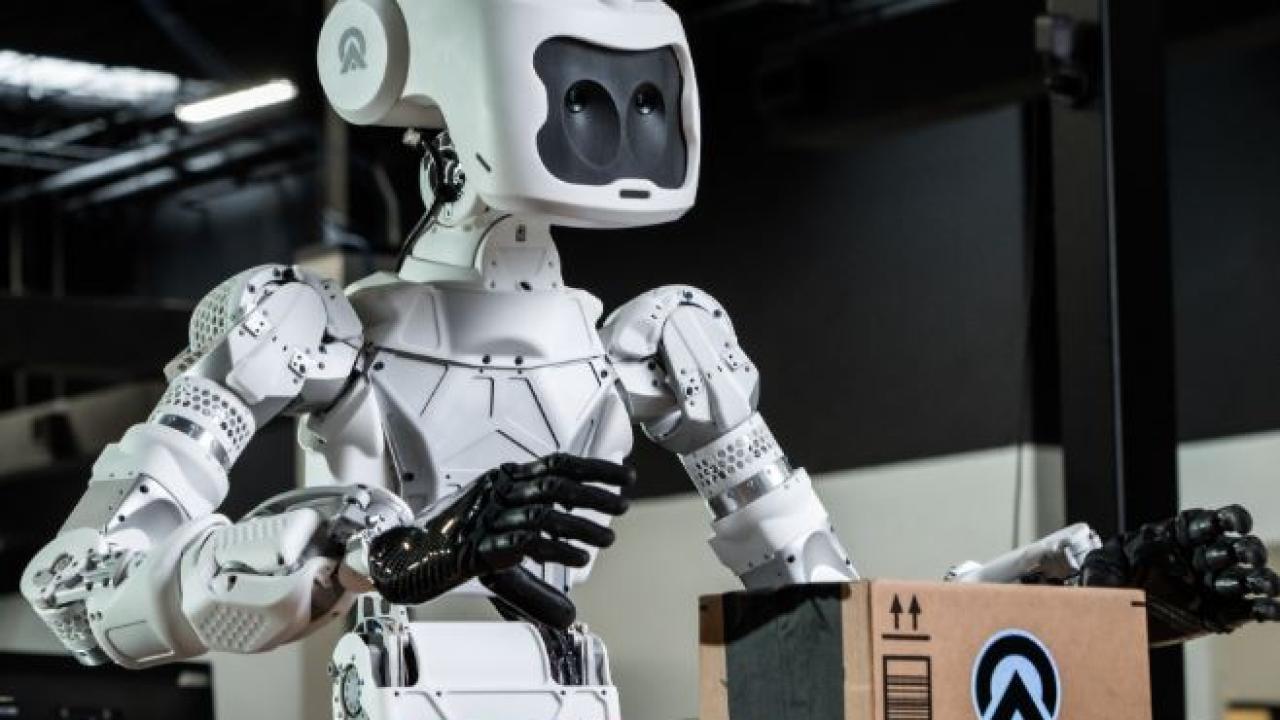

In March, at a manufacturing industry event called ProMat, Agility robots wowed the audience with demonstrations of warehouse tasks such as picking boxes from shelves and placing them on conveyor belts completely autonomously .

Of course, there are already plenty of warehouse and manufacturing robots that use wheels instead of legs. And storage centres can be designed to make clever use of conventional automation, such as conveyor belts.

But Melonee Wise, Agility’s chief technology officer, acknowledges that there are many situations where using legs on these machines is more beneficial, especially at companies that can’t afford to completely remake their operations around automation. Humanoid robots can more easily navigate stairs, ramps and uneven ground, squeeze into tight spaces and crouch or reach while working, says Wise, who recently joined the humanoid team and was most recently CEO of Fetch Robotics, which makes wheeled robots for warehouses.

“The market is ready,” says Wise, adding that the main challenge will be to build trust: “The secret to success in robotics is to fail gracefully.” They may not have been funny, but the clumsy robots in DARPA’s challenge were way ahead of their time.